Custom hardware development involves creating bespoke electronic systems custom to specific needs, offering notable benefits over off-the-shelf solutions. It’s a meticulous process aimed at optimizing the hardware development process for cost reduction and performance improvement. When done right, custom hardware can integrate advanced technologies, leading to better performance, reduced developmental costs, and improved reliability. Engaging in this process not only addresses unique business requirements but also provides a competitive edge through improved efficiency and tailor-made functionality, especially for tech-driven startups aiming for market-ready products.

Throughout my journey in custom hardware development with Datics AI, I have witnessed how custom solutions can transform ideas into functional, efficient technologies. My experience in spearheading projects has consistently focused on aligning innovative hardware solutions with business objectives to maximize success.

Explore more about custom hardware development:

– custom AI software

– custom enterprise solutions

Understanding Custom Hardware Development

Custom hardware development is a journey that transforms an idea into a physical product custom to meet specific needs. This process involves several stages, each critical to ensuring the final product is both efficient and effective.

The Hardware Development Lifecycle

The hardware development lifecycle is a comprehensive process that begins with understanding the requirements and ideation. This stage involves identifying the specific needs the hardware must address and brainstorming potential solutions.

Once the requirements are clear, the design phase kicks in. Here, engineers create detailed plans and schematics for the hardware, ensuring all components will work together seamlessly. This step is crucial for setting the foundation of a successful product.

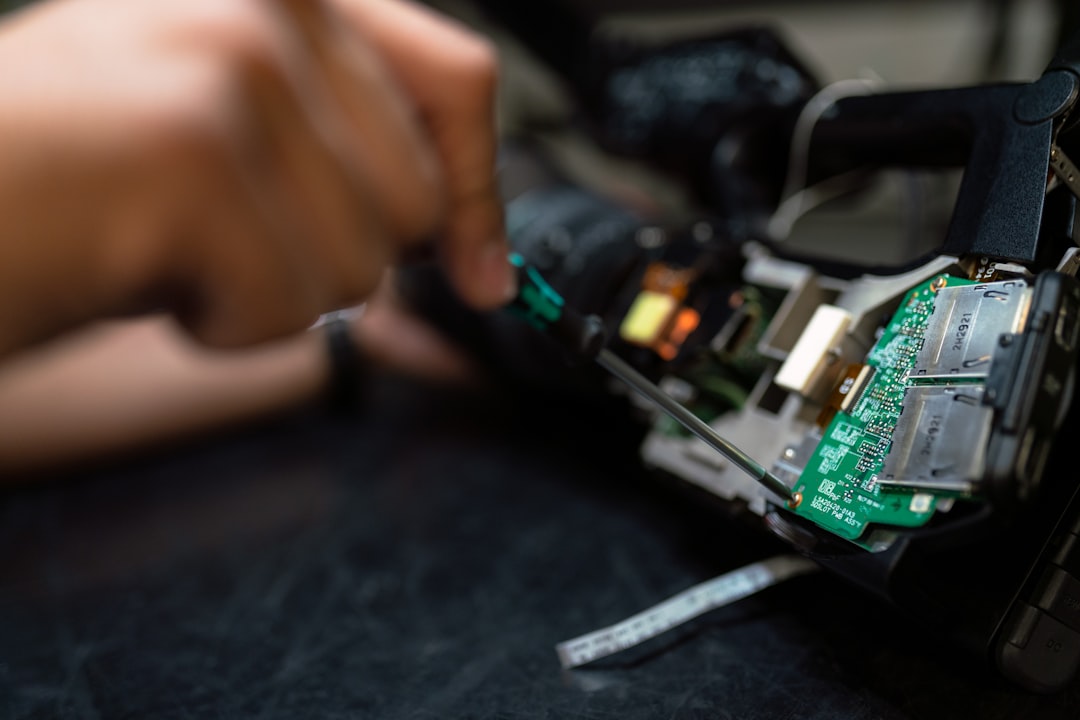

Next comes manufacturing, where the design is turned into a physical prototype. This stage involves assembling the components and building the hardware. It’s an iterative process that often requires adjustments and refinements.

After manufacturing, rigorous testing is conducted to ensure the hardware functions as intended. This includes hardware testing, software testing, and system testing to validate performance and reliability.

Following successful testing, the product is ready for distribution. It is then used in its intended environment, where it must perform reliably and efficiently.

Finally, the lifecycle includes maintenance and eventual disposal. Regular updates and repairs are necessary to keep the hardware functioning optimally, and end-of-life considerations ensure environmentally responsible disposal.

Benefits of Custom Hardware Development

Custom hardware development offers several advantages that can significantly improve a business’s operations:

Availability: Custom hardware is designed to meet specific needs, ensuring that it is always available and custom to the unique requirements of the business.

Performance: By optimizing the design and components, custom hardware can deliver superior performance compared to generic, off-the-shelf solutions.

Security: Custom solutions can incorporate advanced security features, offering improved protection against potential threats.

Cost: While the initial investment might be higher, custom hardware can reduce long-term costs through better efficiency and reduced need for modifications.

Innovation: Custom hardware allows businesses to integrate the latest technologies and innovations, providing a competitive edge in the market.

Incorporating these benefits, custom hardware development stands out as a strategic approach for businesses aiming to optimize their operations and innovate effectively.

Key Phases in Custom Hardware Development

Custom hardware development is a journey, and each phase plays a crucial role in changing an idea into a tangible product. Let’s explore these key phases:

Research and Planning

The first step in custom hardware development is understanding the purpose of the product. This involves defining the goals and the specific needs it must address. Once the purpose is clear, it’s time to dive into the details.

Research focuses on identifying the components required and assessing their interoperability. This is where we lay the groundwork for the design. It’s crucial to ensure that all components will work seamlessly together. This phase sets the stage for everything that follows.

Prototyping and Firmware Development

After laying the groundwork, the next step is building Prototype 1. This initial prototype includes the core components and the firmware necessary to make them function. Firmware acts as the software brain that controls the hardware.

Once Prototype 1 is tested and refined, we move to Prototype 2. This stage involves integrating the electronics with mechanical elements, ensuring the hardware fits well into its casing. The design of the casing is crucial for protecting the components and ensuring the product is user-friendly.

Testing and Validation

Testing is where the rubber meets the road. It’s essential to conduct thorough hardware testing to ensure everything works as intended. This includes:

- Software Testing: Ensuring that the firmware interacts correctly with the hardware.

- System Testing: Evaluating the entire system to make sure all parts work together.

- Validation and Certification: This step checks that the product meets industry standards and regulations, gaining certifications as needed.

Testing is iterative. It involves making improvements and adjustments until the product meets all requirements. This phase is critical for identifying and fixing any issues before the product goes to market.

Improvements and Sustainment

Even after a product is launched, the journey doesn’t end. Ongoing improvements and updates are necessary to sustain the product’s performance. This includes firmware updates and hardware tweaks based on user feedback and technological advancements.

Final Steps

The last steps involve working closely with the customer to ensure the product meets their expectations. This phase includes distribution and support, ensuring the product is ready for use in its intended environment.

By following these phases, custom hardware development can effectively address specific needs, reduce costs, and improve performance. This structured approach ensures that the final product is efficient, reliable, and ready to thrive in the market.

Next, we’ll explore how custom hardware can improve performance, focusing on embedded systems and AI hardware.

Enhancing Performance with Custom Hardware

When it comes to custom hardware development, enhancing performance is key. By tailoring hardware to specific needs, we can achieve remarkable improvements in speed, efficiency, and capability. Let’s explore how embedded systems and AI hardware play a role in boosting performance.

Embedded Systems and Rapid Prototyping

Embedded systems are the backbone of many modern devices. They integrate hardware and software to perform specific functions within a larger system. With the rise of IoT and smart devices, the demand for efficient embedded systems has skyrocketed.

One way to improve performance in embedded systems is through rapid prototyping. This approach allows developers to quickly create and test prototypes, making iterative improvements along the way. Rapid prototyping accelerates innovation by enabling faster experimentation and refinement of ideas.

AI and Custom Chip Development

As AI continues to revolutionize industries, the need for specialized hardware has grown. AI hardware like GPUs and TPUs are designed to handle the intense computational demands of AI workloads. These domain-specific architectures (DSAs) outperform general-purpose CPUs, offering significant performance gains.

The development of custom chips for AI applications is a game-changer. These chips are optimized for specific tasks, such as machine learning and data processing, leading to dramatic improvements in speed and energy efficiency. According to McKinsey, DSAs are expected to account for roughly $90 billion in revenue by 2026, highlighting their growing importance in the semiconductor market.

By focusing on advanced technologies, custom hardware development can deliver cutting-edge solutions that are both powerful and efficient. This not only improves performance but also opens up new possibilities for innovation across various domains.

Next, we’ll dive into how custom hardware development can help reduce costs while maintaining high performance.

Reducing Costs in Custom Hardware Development

When it comes to custom hardware development, reducing costs is as crucial as enhancing performance. By implementing strategic approaches like Design for Manufacturing (DFM) and Design for Assembly (DFA), companies can significantly cut down on expenses while ensuring high-quality production.

Design for Manufacturing and Assembly

DFM and DFA are methodologies aimed at simplifying the manufacturing and assembly processes. They focus on error elimination and improving efficiency, leading to cost savings.

DFM involves designing products in a way that makes them easier and cheaper to manufacture. This includes selecting materials and components that are readily available and easy to work with. By considering the manufacturing process early in the design stage, companies can avoid costly redesigns and production delays.

DFA focuses on designing products that are easy to assemble. This means reducing the number of parts, using standard components, and ensuring that assembly can be done quickly and accurately. By streamlining the assembly process, companies can reduce labor costs and minimize the risk of errors.

An effective DFM and DFA strategy not only reduces costs but also improves product quality and reliability. A study found that by applying these principles, one organization was able to reduce product configuration costs by 10 to 15 percent and support costs by 15 to 20 percent.

End-of-Life and Cost-Reduction Redesigns

End-of-life (EOL) redesigns are another powerful tool for cost reduction. As technology evolves, older products may become obsolete or too expensive to produce. By redesigning these products with new technology, companies can extend their lifecycle and reduce costs.

Cost-reduction redesigns involve reevaluating existing products to identify opportunities for cost savings. This may include using new materials, simplifying designs, or incorporating more efficient production techniques.

Product retirement is also an important consideration. When a product reaches the end of its life, companies must decide whether to retire it or redesign it with updated technology. This decision should be based on market demand, production costs, and potential profitability.

By embracing EOL redesigns and focusing on cost-reduction strategies, companies can maximize the value of their products while minimizing expenses. This not only helps in maintaining a competitive edge but also ensures sustainability in product development.

In the next section, we’ll address some frequently asked questions about the hardware development process.

Frequently Asked Questions about Custom Hardware Development

What is the hardware development process?

The hardware development process is a structured approach to creating custom hardware solutions. It begins with defining the requirements—understanding the needs and goals of the project. This is followed by the design phase, where detailed plans and schematics are created.

Once the design is finalized, the manufacturing phase begins. This involves producing the hardware components and assembling them into a working product. Testing is crucial at this stage to ensure the hardware functions as intended and meets quality standards.

After successful testing, the product moves to distribution, where it is delivered to users or clients. The use phase involves the actual application of the hardware in real-world scenarios. Throughout its lifecycle, the hardware requires maintenance to address any issues and keep it operational.

Finally, at the end of its useful life, the hardware is disposed of or recycled, completing the development process.

How long does hardware development take?

The timeline for hardware development can vary greatly depending on the complexity and scope of the project. Typically, it can take anywhere from 6 months to 5 years. Simple projects may be completed quickly, while more complex ones, especially those requiring certification, can take much longer.

Certification requirements, such as FCC or CE marking, often add time to the development process. These certifications ensure that the hardware complies with regulatory standards, which is essential for market entry.

What does a hardware design engineer do?

A hardware design engineer plays a pivotal role in the creation of computer hardware and equipment. Their primary responsibilities include designing, developing, and validating new hardware components.

Design: Engineers create detailed plans and schematics for hardware products. They consider factors like performance, cost, and manufacturability.

Develop: Once the design is complete, engineers oversee the development and assembly of prototypes. They work closely with manufacturing teams to bring their designs to life.

Validate: Testing and validation are critical. Engineers ensure that the hardware meets all specifications and functions correctly under various conditions.

Hardware design engineers are essential to the success of any custom hardware development project. Their expertise ensures that the final product is innovative, reliable, and meets the needs of users.

In the next section, we’ll explore how Datics AI can support your custom hardware development needs.

Conclusion

At Datics AI, we understand the complexities and challenges involved in custom hardware development. Our mission is to transform your innovative ideas into market-ready products, providing comprehensive support from concept to launch. With our meticulous attention to detail, we ensure that every stage of your project is handled with care and expertise.

Innovation is at the core of what we do. By leveraging cutting-edge technologies and methodologies, we deliver solutions that not only meet but exceed the expectations of our global clients. Our team is committed to staying at the forefront of technological advancements, enabling us to create hardware that is not only efficient but also future-proof.

Here’s why partnering with Datics AI for your custom hardware development is a smart choice:

Comprehensive Support: From initial research and planning to prototyping, testing, and beyond, we offer end-to-end services that cover every aspect of the hardware development process. This ensures a seamless journey from ideation to realization.

Global Reach: Our experience with clients worldwide allows us to bring diverse perspectives and innovative solutions to your project. We understand the unique needs of different markets and tailor our services accordingly.

Commitment to Quality: We are dedicated to delivering high-quality hardware that meets rigorous standards. Our thorough testing and validation processes ensure that your product is reliable and ready for real-world use.

Ready to start on your hardware development journey with us? Explore our services to see how we can help you achieve your goals and transform your vision into reality.

By choosing Datics AI, you’re not just getting a hardware solution; you’re gaining a partner committed to your success. Let’s craft your success story together.